Idraulica Sighinolfi Albano is able to design and manufacture hydraulic cylinders from 32mm up to 650mm bores, with length up to 11 metres.

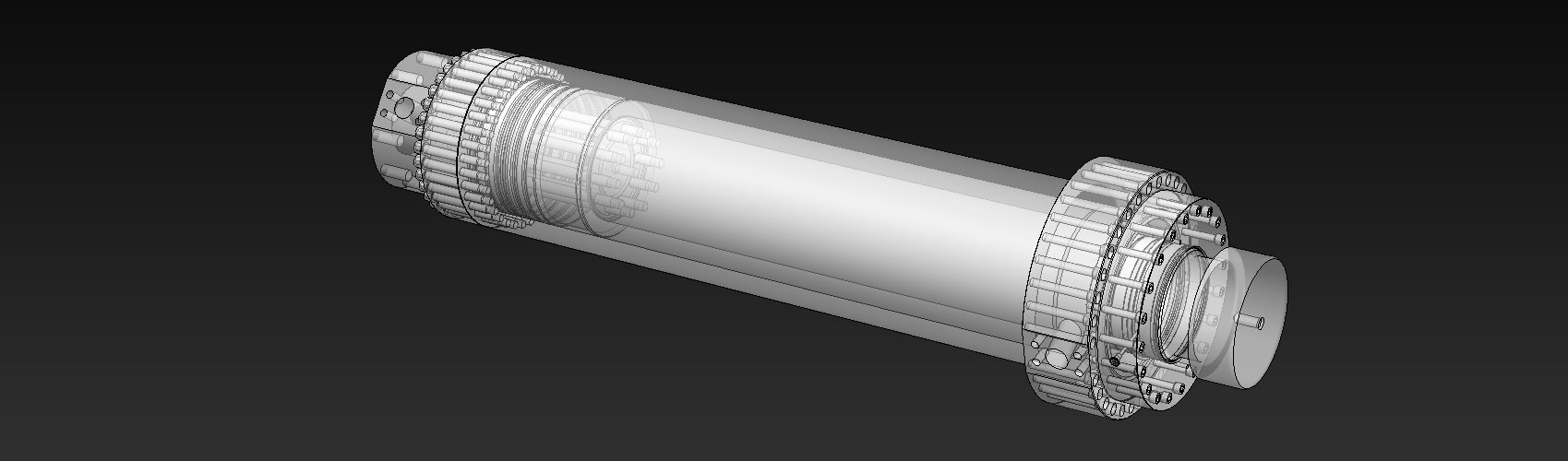

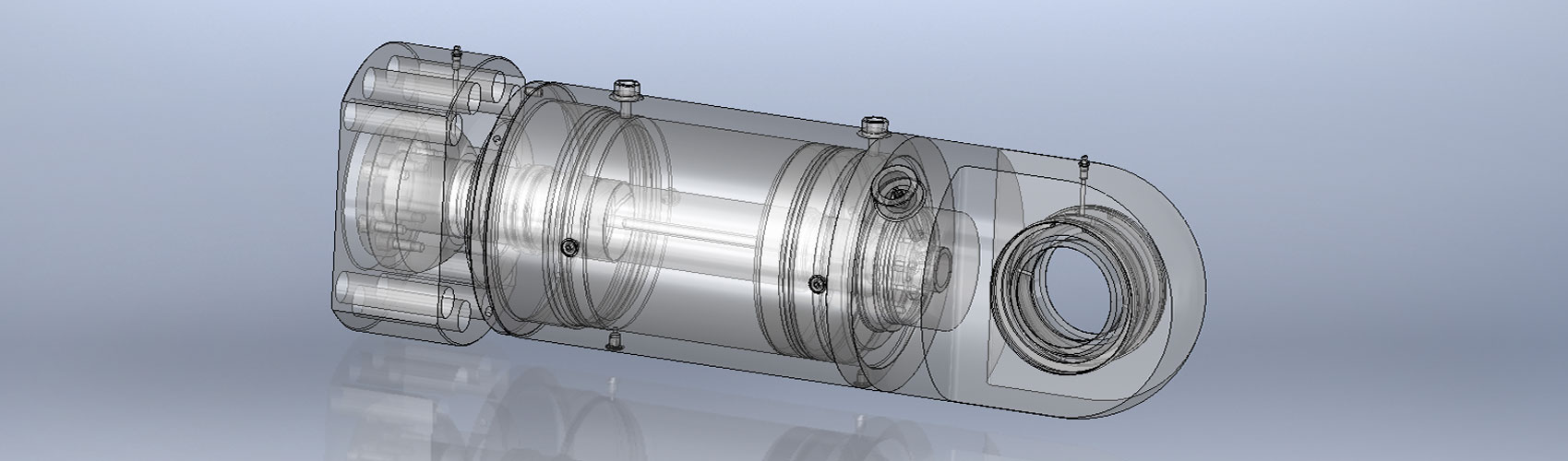

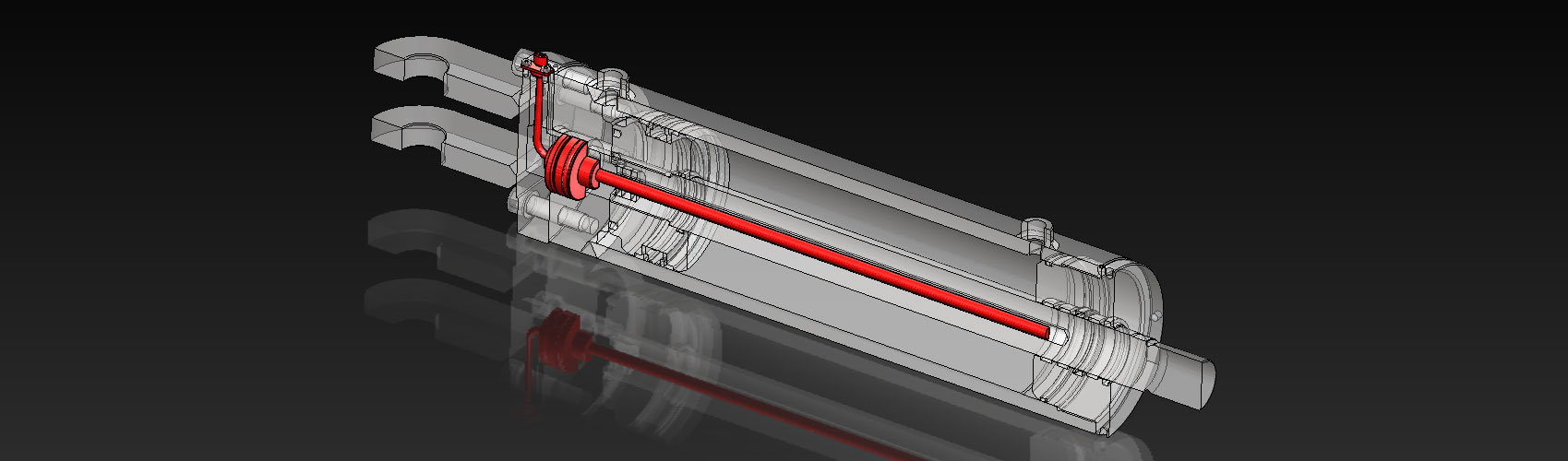

After a first collection of information useful to design the cylinders, we start to draw the cylinder with CAD 3D integrated with FEM Analysis and calculation to achieve third-party certifications (DNV, ABS, GL, LR, BV) and ensure in compliance with every request.

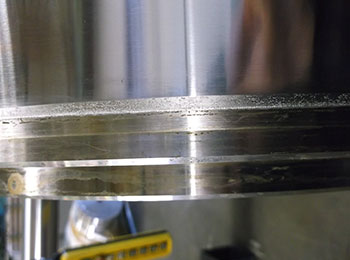

In the last part of the process, there is the assembly and the final check supervision: our staff of engineers and highly specialized experts are at customers’ disposal to guarantee the highest level of quality and reliability in every step of the process.